THE COMPLETE PACKAGE

By utilising the facilities and skills offered by our group company EschmannStahl, we are able to support our local customer base with a complete steel and heat treatment service. Modern heat treatment processes ensure high quality standards and material reliability with shortened process cycles.

OUR PROCESSES:

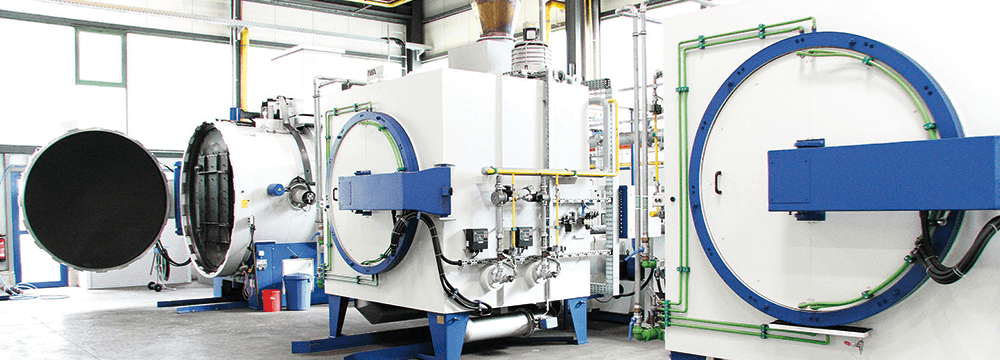

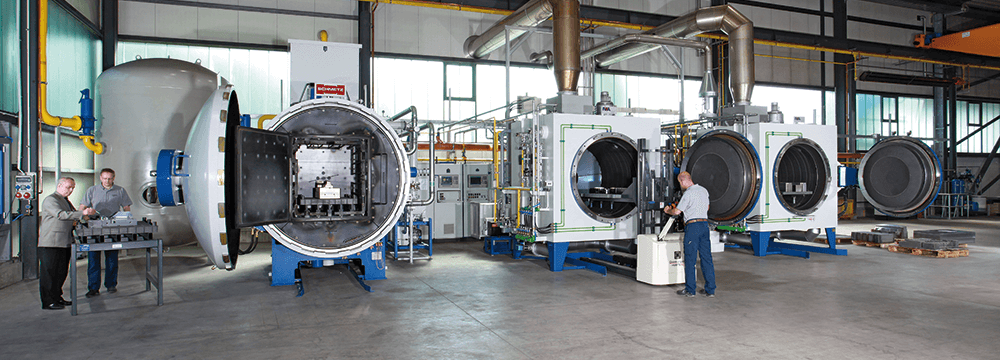

Vacuum Hardening/Tempering

Hardening in a vacuum is particularly suitable for injection mould tools and inserts. The vacuum heat treatment process allows high dimensional accuracy and minimal distortion whilst remaining an environmentally friendly process. The process can be computer controlled to ensure material hardness repeatability and due to the vacuum environment, there is little to no contamination to the steel from Carbon, oxygen and other gases preventing scaling and decarburization on the tool surface eliminating the need to carry out expensive reworking.

Vacuum Annealing

After vacuum hardening, the tool is reheated once again to a pre-defined temperature to enable the tool to develop further properties such as hardness, toughness, ductility and wear resistance. Annealing in a vacuum has the advantage that the heating and cooling can be better controlled, which is favourable in regards to the shape and dimensional stability of the tool.

Isothermal Quenching

The tool is submerged into a quenching fluid, the most effective quenching media being water when maximum hardness is required. This allows the tool to be cooled evenly so that the temperatures throughout the workpiece remains uniform minimizing cracking and distortion. This quenching method is recommended for complex geometries and highly stressed parts, quenching can also be accomplished using inert gases such as nitrogen, helium and argon.

Gas Nitriding

Gas nitriding allows large batch sizes to be heat-treated all at once; the process diffuses gases onto the surface of the tool/component creating a nitride layer. Tools to be gas nitrided should ideally be in the hardened and tempered condition, requiring nitriding to take place at a lower temperature to that of which it was tempered at. Advancements in technologies allow modern computer control of the atmospheric gases allowing the nitriding results to be closely monitored. Most UK aircraft quality steel grades can be easily nitridable, along with stainless steels and certain tool steels (H13 & P20) .

All our heat treatment processes are carried out in a safe and controlled environment to highest of quality standards. Combined with various hardness testing options and complete documentation of conformity Intersteel are able to offer a complete steel and heat treatment service compliant to NADCA standards where specified.